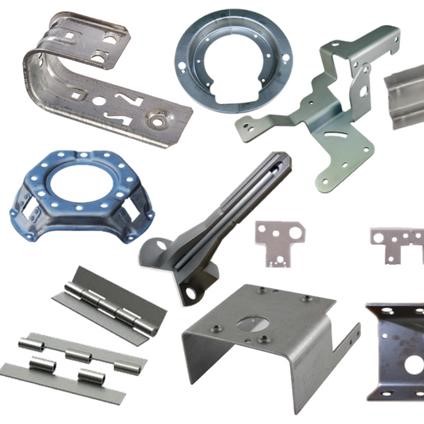

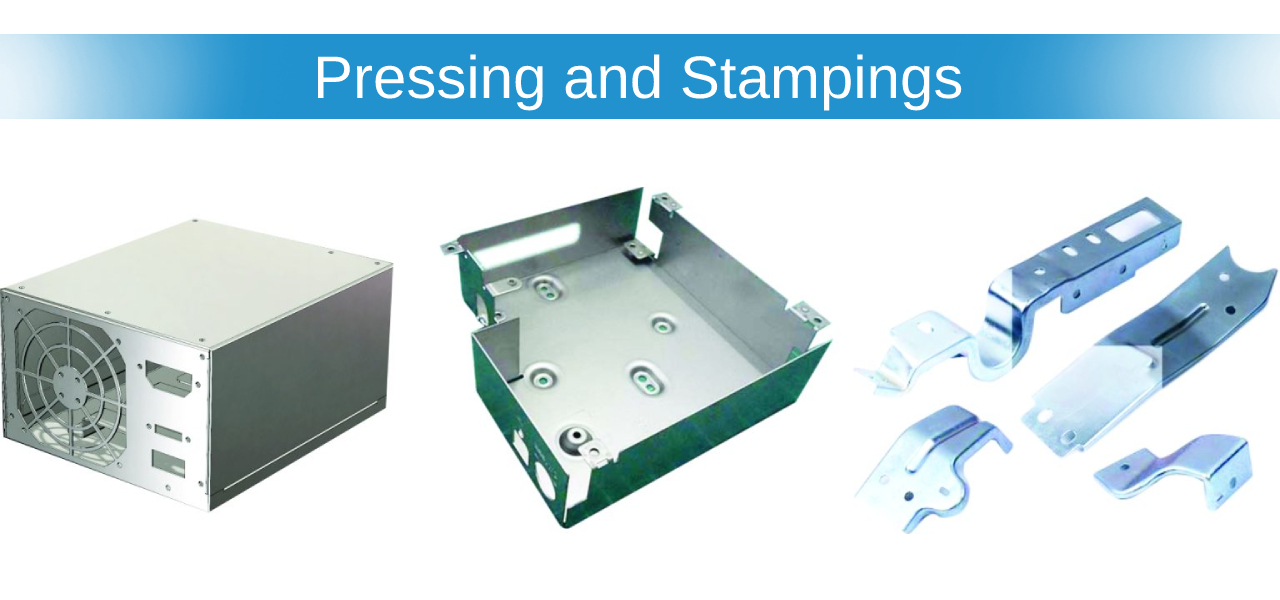

Daksh Global’s high-quality, precision metal stamping capabilities forms and processes a wide range of metals to meet application-specific requirements. We provide custom metal shapes and parts produced using stamping and forming processes and can form complex shapes based on production tooling.

Metal Stamping & Forming Processes

- Deep Draw stamping

- Progressive Die stamping

- Transfer Press stamping

- Prototype & Short Run stamping

Materials

- Aluminum Alloys

- Steel Alloys

- Stainless Steel Alloys

- Brass

- Copper Alloys

- Galvanized Steel

Secondary Metal Finishing Services

- Heat Treating – Improve properties, performance and durability

- Chrome plating – Cosmetic and decorative finishes

- Passivation – Corrosion prevention

- Powder Coating – Variety of colors and outstanding durability

- Anodizing – Corrosion resistance & cosmetic surface finishes

- Zinc Plating – Corrosion and oxidation prevention

- Tin Plating – Commonly used in some industries

- Black Oxide – Corrosion resistant finish

- Gold & Silver Plating – Cosmetic and/or electronics for corrosion resistance

- Annealing – To increase ductility and reduce hardness

Industries & Applications

- Electronics – Telecom, computer, server, data communications, connectors and electronic components

- Automotive – Components, sub-systems and other vehicle applications

- Lighting – Custom components for exterior, interior lighting applications

- Marine – Applications include connectors, fittings, enclosures, housings, caps, covers and couplings

- Medical – Medical products, surgical devices, equipment, pumps, motors, probes

- Construction – Hardware and metal components

- Electrical – Components and assemblies for electrical / wiring components and systems

- Aerospace – Electronic components, hardware, sub-assemblies, couplings and fittings